Large-Format 3D Printing Systems for Mission-Critical Applications

Trusted by R&D labs and aerospace innovators to design, build, and deliver precision-engineered machines that push the limits of additive manufacturing.

How it Works.

Discover → Design → Manufacture → Deliver

Discover

Identify the scope, constraints, and goals of your project.

Design

Create and iterate on the perfect machine solution.

Manufacture

Precisely build your custom machine to specifications.

Deliver

Deploy the finished product with full support and follow-through.

Core Differentiators

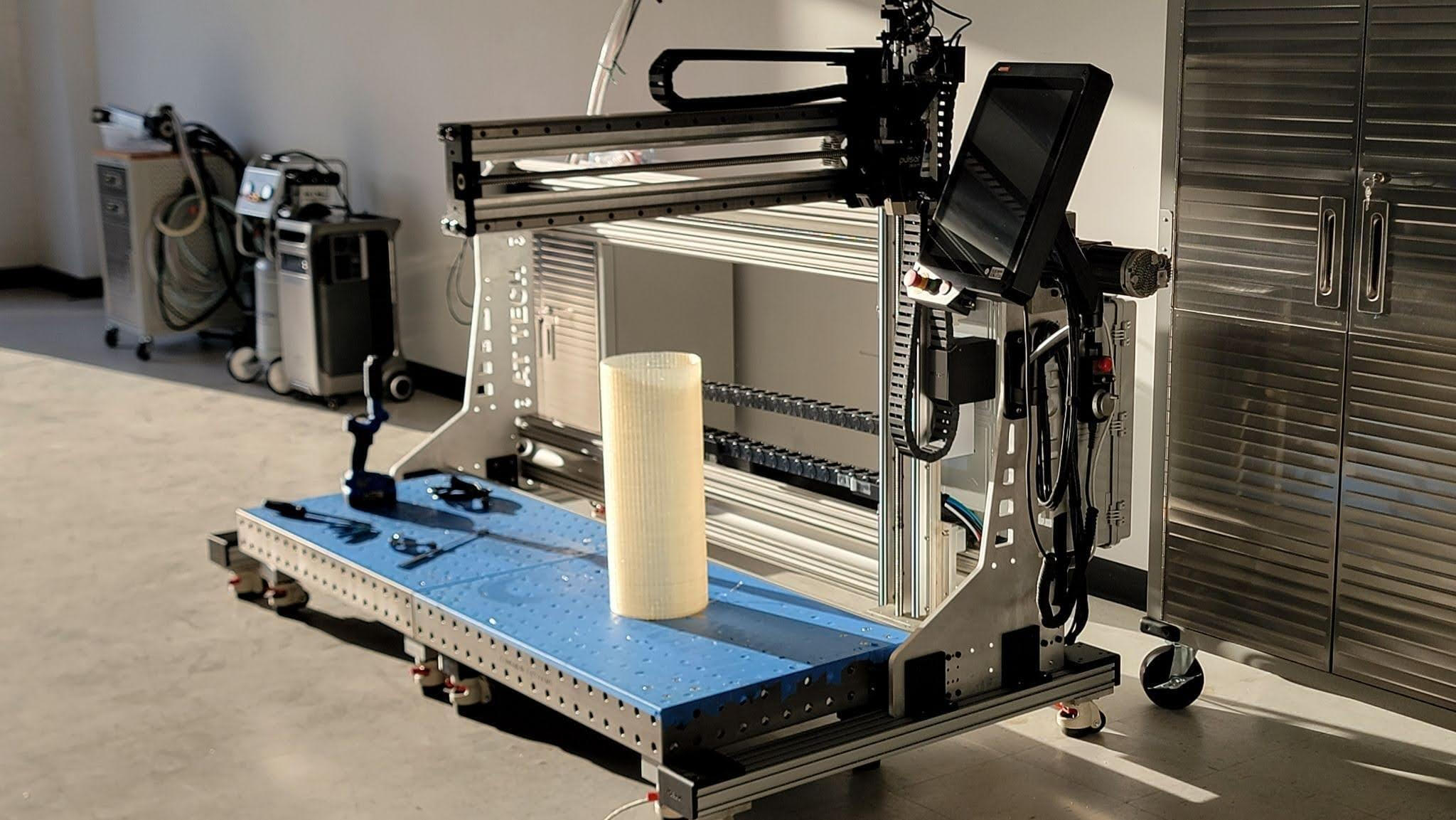

Ideal for R&D

Full Machine Access

Printatron machines are built for innovation. Every system is designed with full accessibility, allowing researchers to reach, adjust, and modify components with ease. This hands-on flexibility enables rapid prototyping, iterative testing, and direct integration into R&D environments. A user-friendly interface reduces the learning curve, ensuring even complex operations can be performed with minimal training. Perfect for labs pushing the boundaries of technology.

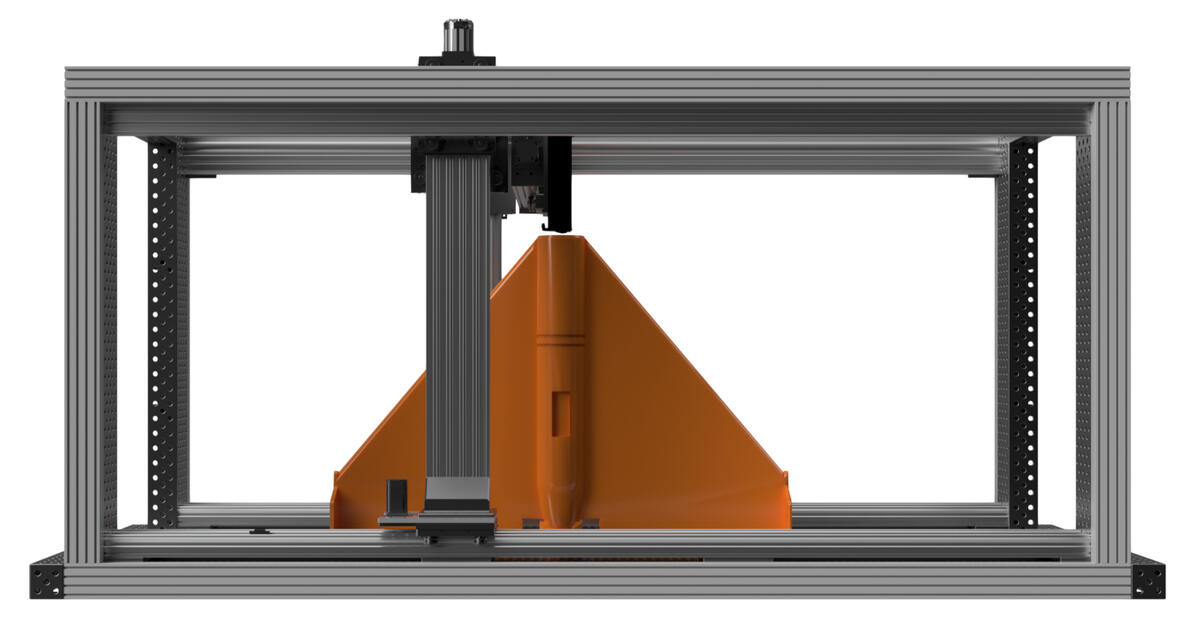

Modular Gantry Design

Precision with Flexibility

Our modular gantry systems deliver high precision while adapting to your workflow. With expandable build volumes and multiple configuration options, Printatron machines can be tailored to fit specific project requirements. The modular design supports multi-step processes on a single platform, reducing downtime and streamlining operations. Components are engineered for quick replacement without special tools—keeping productivity high and maintenance simple.

Scalable Platform

Future-Proof Your Workflow

Printatron platforms grow with you. From compact units for research to expansive machines for large-scale production, every system can be scaled and customized with different tools, gantry styles, and add-ons. This adaptability ensures seamless progression from prototyping to production without the need to replace your entire system—protecting your investment while evolving with your goals.

Prior Projects

ERDC (U.S. Army)

Delivered a multi-material, 5-axis large-format printer— 60% faster prototyping

Fathomwerx (U.S. Navy)

Engineered a rugged, large-format printer optimized for classified maritime prototyping. U.S. Navy

Firehawk Aerospace

Developed and deployed a specialized large-scale printer for propulsion component prototyping—enabling next-gen aerospace testing. NDA-protected

Pivotal (Opener Aero)

Delivered custom 5-Axis containerized composite production system.

Capabilities

Additive Manufacturing (AM)

High-flow filament, pellet extrusion, and DED for versatile large-format builds.

Subtractive Manufacturing (SM)

Precision 3-/5-axis CNC and laser machining for post-processing and fine features.

Hybrid Manufacturing (HM)

Seamlessly combines additive and subtractive for fully integrated, end-to-end workflows.

Printatron’s machine solutions are turn-key production platforms designed for large build volumes. Each machine is highly configurable, offering multiple tool options, gantry styles, and additional features tailored to meet diverse manufacturing needs.